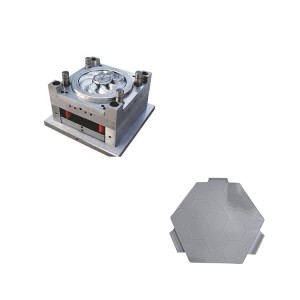

P&M kev teeb liab teeb iav yas pwm customized

2022 P&M kev teeb liab teeb iav yas pwm customized

Cov txheej txheem ntau lawm & tib neeg ua haujlwm ib puag ncig

Professional pwm tsim & tsim

Peb muaj ntau tshaj 10 xyoo ntawm kev paub hauv pwm tsim thiab tsim khoom.Peb tau cog lus tias yuav siv cov ntaub ntawv zoo tshaj plaws los ua koj cov pwm los xyuas kom meej tias lawv yuav tsim cov khoom zoo tshaj plaws rau koj.

Peb yog ob qho tib si lub npe thiab lub Hoobkas, nrog ntau txhiab hom khoom, nrog cov kev pabcuam zoo thiab zoo raws li thawj zaug, peb tsis muaj qhov kev txiav txim yam tsawg kawg nkaus, qhia peb cov kev xav tau, peb tuaj yeem muab cov kev pabcuam tshaj lij rau koj. .

Yas Txhaj Mould ua

1.Samples/Drawing & Requirement los ntawm koj

2.Mould tsim: peb yuav sib txuas lus thiab sib pauv tswv yim nrog koj tom qab koj tso qhov kev txiav txim.

3.Material Purchase: Hlau txiav thiab Pwm puag tooling.

4. Kev sib dhos.

5.Kev tshuaj xyuas pwm: ua raws thiab tswj cov cuab yeej ua haujlwm.

6.Mould kuaj: Peb yuav qhia rau koj hnub tim.Thaum yuav xa cov qauv kuaj xyuas daim ntawv qhia & kev txhaj tshuaj tsis muaj cov qauv rau koj!

7.Koj cov lus qhia & kev lees paub rau kev xa khoom.

8.Ready ua pwm ua ntej packing.

9.Peb muab txhua yam sib txawv ntawm cov yas txhaj tshuaj pwm, tshuab pwm, silicone pwm, tuag casting pwm kev pab cuam.

Yas molding Specification

1. Cov chaw tsim khoom, tsim, ntau lawm txhaj pwm thiab stamping pwm zoo tswj

2. nplua nuj export kev yas txhaj tshuaj pwm thiab stamping pwm

3. Tsim nyog tus nqi tsim pwm

4. Kab noj hniav: ib leeg los yog raws li koj xav tau kab noj hniav

5. Kev Kho Mob: S45C Pretreat> 25Hrc, Thiab Nitriding 6. Pwm Hlau: Cavity, Core thiab swb: P20, 2738,213

6 muaj Moldbase: LKM muaj

7. Txuj: DEM, HUSKY, muaj

8. Kub khiav: raws li koj xav tau

9. Lub Sijhawm Lub Neej:> 300 txhiab zaug

10. Pob: Plywood case, anti-xeb xim