Tuam Tshoj kev cai molding txhaj pwm tsim dej khob yas lub raj mis cap pwm

2021 Yuyao Cixi Ningbo Zhejiang pib qhov chaw stamping tuag / pwm / pwm / qhov muag teeb thiab yas txhaj tshuaj molding

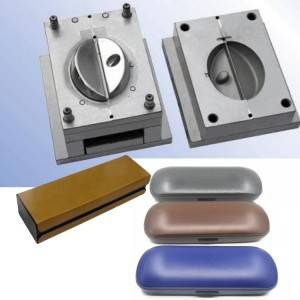

Yam khoom: Ningbo Pwm / Yas Pwm / pib qhov chaw stamping tuag / pwm / molding / Txhaj yas pwm / Yas txhaj molding / Yas Txhaj Pwm / pwm txiag / tshuab luam ntawv pwm / Yas toolings txiag Specifications.

1. Hais txog peb lub tuam txhab

1) Peb tau ua cov teeb pom kev zoo thiab cov khoom siv teeb pom kev zoo rau 14 xyoo, nruab nrog 30 teeb pwm ua cov cuab yeej, cov kws tshaj lij CAD, CAM, CAE thev naus laus zis thiab cov cuab yeej kuaj tshwj xeeb.

2) 2012 peb lub hnub qub pwm Hoobkas.

3) Peb cov neeg tuag muaj xws li: tsheb qhov chaw, khoom siv hauv tsev, khoom siv kho mob, khoom siv hauv tsev, khoom siv hluav taws xob thiab hluav taws xob, khoom siv tes ua thiab kev tsim vaj tsev thiab lwm yam ...

4) Peb yuav Qhia koj tus nqi zoo tshaj plaws raws sijhawm, thov muab cov ncauj lus kom ntxaws thaum xa cov lus nug.

5) thov qhia cov khoom siv molding, qhov hnyav, txhua xyoo yuav khoom kom muaj nuj nqis, lub hom phiaj ua tiav thiab lwm yam kev cai tshwj xeeb (xws li: UV, VO, painting, chrome, screen printing, sib dhos thiab lwm yam).

2.Discription ntawm qhov muag teeb

| Yam khoom | Kev cai yas pwm |

| Pwm Sijhawm | 20-35 hnub |

| Lub sijhawm khoom | 7-15 Hnub |

| Mod precision | +/- 0.01 hli |

| Pwm lub neej | 50-100 lab txhaj tshuaj |

| Cov khoom siv pwm | P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

| Pwm kab noj hniav | Ib kab noj hniav, ntau kab noj hniav los yog tib yam khoom sib txawv ua ke |

| Qhov system khiav | Kub khiav, txias khiav |

| Kev kho saum npoo | Cov lus corrosion, Daim iav polish, Frosted nto, Dermatoglyph |

| Pwm txheem | HASCO, DME lossis raws li kev cai thov |

| Cov txheej txheem tseem ceeb | Milling, sib tsoo, CNC, EDM, hlau-electrode txiav, carved, electrospark, tshuab dhos, kho deg |

3.Plastic Txhaj Pwm ua

1.Samples/Drawing & Requirement los ntawm koj

2.Mould tsim: peb yuav sib txuas lus thiab sib pauv tswv yim nrog koj tom qab koj tso qhov kev txiav txim.

3.Material Purchase: Hlau txiav thiab Pwm puag tooling.

4. Kev sib dhos.

5.Kev tshuaj xyuas pwm: ua raws thiab tswj cov cuab yeej ua haujlwm.

6.Mould kuaj: Peb yuav qhia rau koj hnub tim.Thaum yuav xa cov qauv kuaj xyuas daim ntawv qhia & kev txhaj tshuaj tsis muaj cov qauv rau koj!

7.Koj cov lus qhia & kev lees paub rau kev xa khoom.

8.Ready ua pwm ua ntej packing.

9.Peb muab txhua yam sib txawv ntawm cov yas txhaj tshuaj pwm, tshuab pwm, silicone pwm, tuag casting pwm kev pab cuam.

4. Cov duab

Vim li cas thiaj xaiv peb?

1.Peb yog lub Hoobkas tshaj lij nrog ntau tshaj 14 xyoo kev paub

2. Txais OEM tsim: tuaj yeem tsim cov qauv tsim raws li koj xav tau

3.Peb muaj ib pab neeg tsim qauv ua qauv raws li koj txaus siab.

4. Ceev ceev, cov ntaub ntawv zoo silicone raws li cov neeg siv khoom xav tau

5. Kev tswj xyuas nruj ua ntej ua zaub mov xa tuaj

6.Peb tshwj xeeb tsom rau kev pab cuam tom qab muag

5. Peb Exhibition, tus khub thiab daim ntawv pov thawj